Getting My Motorcycle Parts New Zealand Specialists To Work

Wiki Article

The Of Motorcycle Parts New Zealand Specialists

Table of ContentsThe Main Principles Of Motorcycle Parts New Zealand Specialists What Does Motorcycle Parts New Zealand Specialists Mean?How Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.The 3-Minute Rule for Motorcycle Parts New Zealand SpecialistsThe Ultimate Guide To Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists Things To Know Before You BuyWhat Does Motorcycle Parts New Zealand Specialists Do?All about Motorcycle Parts New Zealand Specialists

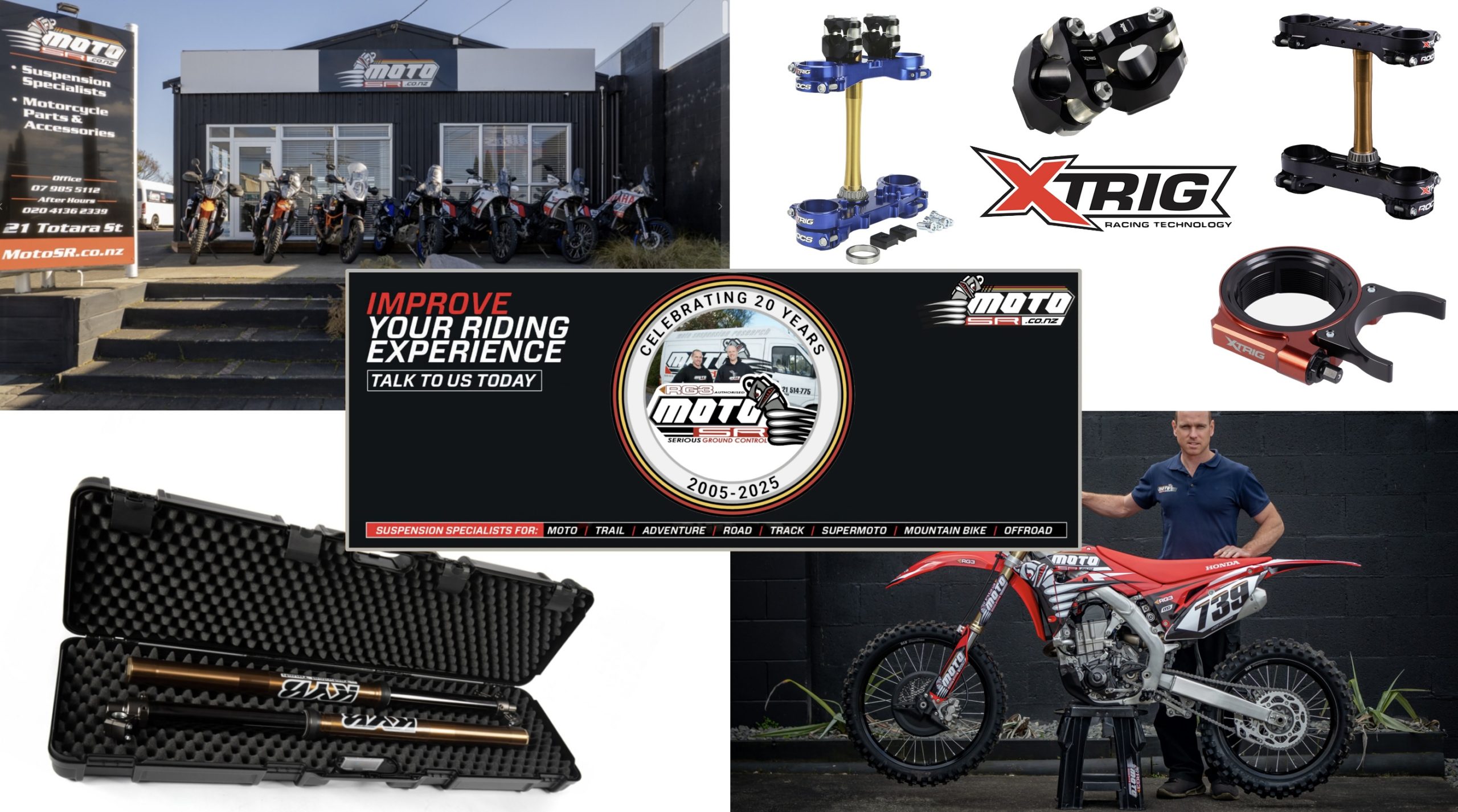

So, connect to one of our experts today.CNC machining technology is promptly becoming the prime focus of numerous various manufacturing procedures around the globe as a direct outcome of its numerous benefits over other techniques. In addition, the industries that produce bikes have hopped on board with this fad. The most innovative firms are now establishing their engine parts and wheels making use of machining strategies originally created for motorbike parts.

On the other hand, the results of industry are the key focus of this short article. Let's get right into it. You may be asking yourself why we use. It is not tough to fathom the aspects that resulted in this result. Since we have your focus allow us explain the reasoning behind this modern development in the motorcycle production industry.

An Unbiased View of Motorcycle Parts New Zealand Specialists

In enhancement, you have complete control over the appearance of the parts, even down to the min details. Periodically, motorcyclists may decide to spruce up their adventure by installing aftermarket elements or changing the bike's makeover.

The Best Strategy To Use For Motorcycle Parts New Zealand Specialists

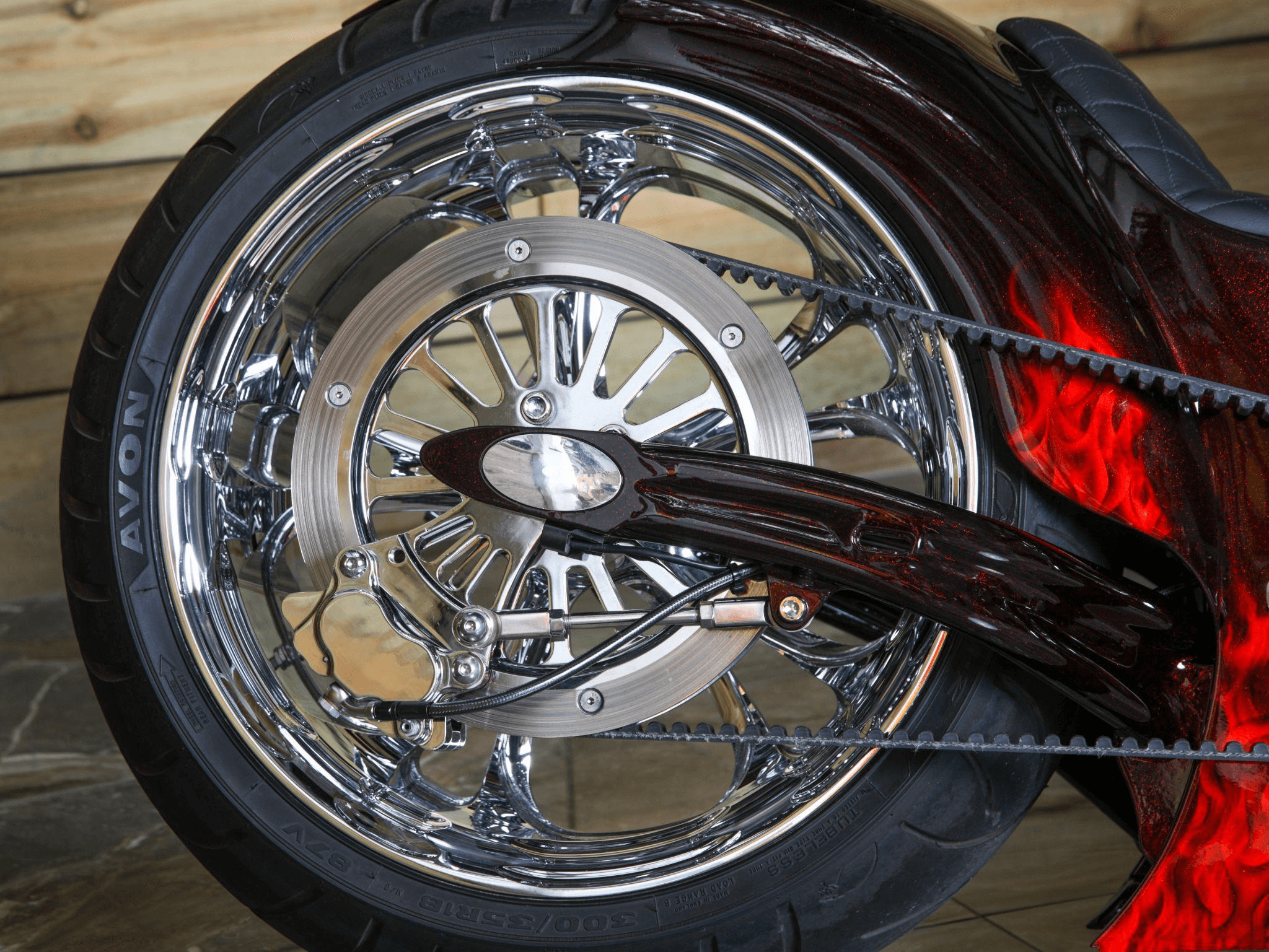

CNC machining may be used to make almost all of a motorcycle's metal and plastic components. To proceed, we'll discuss several machined components for motorbikes.When tailoring the wheels, the disks are where the emphasis must be. The majority of them are constructed out of aluminum. Light weight aluminum alloys are widely known for the outstanding machining capacities that they have. Milling treatments are utilized to acquire the preferred level of wheel customization. One more facet of the motorcycle that may be individualized is the tires.

Not known Factual Statements About Motorcycle Parts New Zealand Specialists

When it involves a car (or a motorcycle), the most important element is the engine. A number of people suggest to it as the "heart" of the vehicle. On the other hand, the camshaft, the cyndrical tube head, and the pistons tend to be intricate and need designs with a high degree of precision.Usage just top quality products, nevertheless, given that these lights are vital for the safety of motorcyclists and other motorists or individuals on the road, especially at night. Motorbike fronts lights have 3 major parts: the light bulb, or site light source, the lens, and the housing.

Milling procedures with a flawless surface would certainly result in the lenses having a reflective quality that is comparable to that of a mirror. The cover, on the various other hand, is not made up of delicate materials; rather, it is built out of challenging polymers that can be machined right into even more detailed patterns.

How Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.

Motorcycle suppliers frequently cast these components, however only for the manufacturing of bespoke parts. Machining on 5 axes in today's globe is the ways by which any kind of design shape might be recognized.The success of the process is contingent on the mill cutters' ability to determine refined and complicated angles accurately. Pick Runsom for your tailored motorbike components! We have the capability to make complex and fashionable components making your motorcycle incomparable. A lot of are crafted from aluminum or steel alloys, each of which has its usages and benefits.

Right here are a couple of instances of metals commonly made use of in bike component machining. Aluminum is the key material made use of by firms concentrating on generating personalized motorbike elements to develop a lot of these parts. In the past, we would construct our engines out of actors iron. On the various other hand, aluminum is rapidly coming to be the material of option, partially as a result of the fact that it is much more lightweight.

Zinc describes an additional metal that is extremely light in weight and has wonderful machining top qualities because of its high mechanical stamina. This product may be formed into almost any form and preserves its measurements well. Even mission-critical components that require a high degree of accuracy might take advantage of their use.

More About Motorcycle Parts New Zealand Specialists

An additional steel that his explanation sees hefty usage in the manufacturing of CNC-customized elements is magnesium. It is amongst the lightest steels that are now available and has superb machinability features and stamina appropriate with its low weight. One of the downsides of magnesium is that its dust may quickly ignite.

Their most typical use in creating different motorbike elements is fasteners, such as screws and bolts. Their low vulnerability to oxidation and rust makes them excellent for this usage.

The Facts About Motorcycle Parts New Zealand Specialists Uncovered

It seems that CNC transforming and milling are the fundamental processes. In enhancement, it needs maintaining bars of product, most usually plastic or steel, in placement and after that turning a reducing tool to eliminate sections of the product as the product is turned.

These approaches are equally essential and produce elements with high precision and regular quality. The processes help improve the general top quality of the machined bike parts.

Motorcycle Parts New Zealand Specialists Things To Know Before You Get This

Report this wiki page